BLOG

Why IoT Development Teams Need Mechanical Engineers

One may think you only really need software engineers in a business that mainly deals with IoT products, but that could not be farther from the truth. Many IoT products are still realized in the physical world, which in turn, leaves the hardware design portion to a mechanical engineer (ME).

Not to mention that the software elements of a product can be updated remotely, while their mechanical design cannot. This puts a considerable amount of pressure on mechanical engineers to ensure seamless interaction between the hardware and software of a product throughout its entire lifespan.

What Role Do Mechanical Engineers Play in Building IoT Products?

Let’s give an example of a very well known product, the Apple Watch. The Apple Watch is a prime instance of a successful IoT product. It connects to your phone via Bluetooth automatically, determines heart rate, sends messages, and much more all simultaneously. Yet without a mechanical engineer, the Apple Watch would have never come to fruition. The mechanical engineer designed the shape of the watch, the curves of the glass, the button wheel, and everything else you can physically touch on it. And after all, what good is an Apple Watch without the watch?

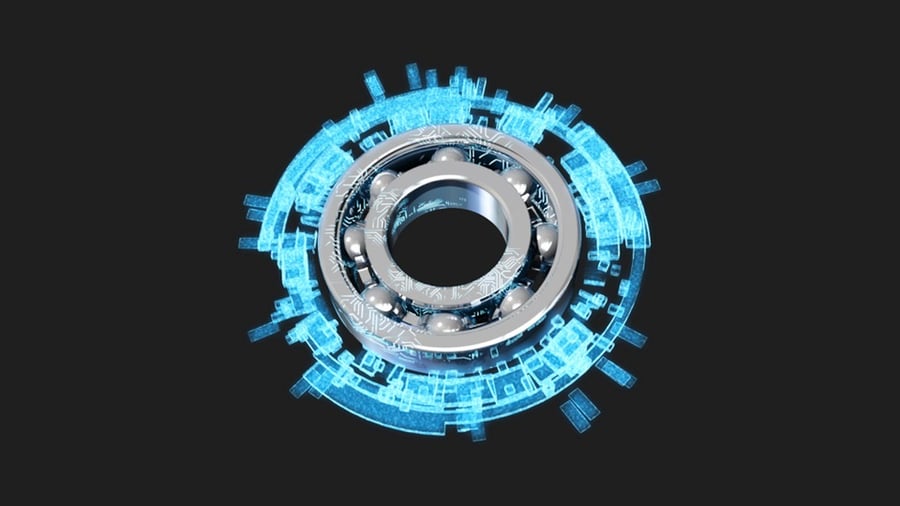

Another great example of mechanical engineering in IoT comes from one of the oldest mechanical devices in history, the bearing. At their core, bearings are simple. They are in your household fans, your cars, and very large manufacturing equipment. Yet if even one fails, an entire operation can be halted until it is fixed. Sure, there are ways to estimate bearing life, but it is a complete gamble. Bearings currently have a “L10” life, which means that in the bearing manufacturer’s theoretical tests, 90 percent of bearings survive that amount of hours. Not to mention these theoretical tests are assumed to be properly lubricated, debris/dust free, no shock or vibration, and perfectly aligned. You can start to see how much of a gamble estimating bearing life really is.

So how are mechanical engineers stepping in to try and resolve this issue? One of the biggest bearing manufacturers, SKF, is providing customers with technology to help install and analyze bearings. The company has also made portable vibration testers that technicians use “like a stethoscope to take the pulse of individual machines during walk-by inspections.” With this technology, instead of estimating bearing life, you can confidently say when a bearing is about to fail. With innovations like this, mechanical engineers and software engineers are working hand in hand to solve problems that have plagued manufacturing facilities for decades.

Okay, you’ve sold me. Now how do I implement them in my workflow?

That’s really the easy part. Your electrical and mechanical engineers can work together to figure out the ideal way to package and size your boards and enclosures. Sometimes these pieces of hardware need to be placed into an environment where there is excessive rain, heat, freezing temps, etc (think of a sensor placed in hot exhaust gas coming off of an engine). Your mechanical engineer can tackle all of that. An adept ME can design your product to live in the elements for as long as you keep updating the software in it, and usually even longer.

Building Complete Products

Let’s face it, not having a mechanical engineer on your team can lose you clients. Having an ME on your team can land clients looking for a product that needs to be built from scratch. If your company is delving deep into the IoT. You’re going to need to build your product from the ground up and from start to finish. With a mechanical engineer, they can get you there. Once you have your idea in mind, your ME can get you home. They can design, help rapid prototyping, and develop your product into a tangible object. That is why here at Very, we believe if you are serious about IoT development, mechanical engineering is a necessity.

Serious IoT Development Requires Serious Mechanical Engineers

Truly innovating the IoT industry as we keep advancing in this field is getting tougher and tougher, but there are many ways mechanical engineering and the IoT industry can still innovate. If your company is developing products that are going to be out in the world, you need a serious mechanical engineer, if not a few, that can get the job done. So you may be asking yourself, “What kind of mechanical engineers should I hire?” Well, ME’s with experience in software is a good start. Still any engineer that can bridge the gap between software and mechanical design and is willing to get down and dirty with the way IoT products are developed is a good bet.

Make no mistake, mechanical engineering is not being phased out within the IoT industry. It is here to stay so we can keep innovating, creating, and bringing your ideas to life.

If you could use some exceptional IoT engineering talent on your next project, feel free to drop us a line.