WHITEPAPERS

Unlock New Revenue Streams With Predictive Maintenance for the Connected Plant

In this guide, we’ll explore methods of leveraging data to optimize your connected plant through predictive maintenance.

Plant maintenance. Everyone knows they should do it, but it’s too easy to deprioritize when there aren’t any visible problems. What can’t be ignored are the long-term costs of neglecting preventative plant maintenance. Forbes reports that, on average, manufacturers face 800 hours of equipment downtime annually, translating to over 15 hours each week. This interruption carries a hefty price tag. Unplanned downtime costs industrial manufacturers as much as $50 billion a year.

For years, maintenance professionals relied on quantitative and qualitative approaches to predict failures and mitigate downtime in their facilities with limited success. New Industrial Internet of Things (IIoT) tools improve on these methods by using machine learning (ML) to take a more data-driven approach.

New insights powered by machine learning create opportunities to optimize maintenance tasks in real-time to maximize the useful life of equipment — all while avoiding disruption to operations.

Types of Maintenance

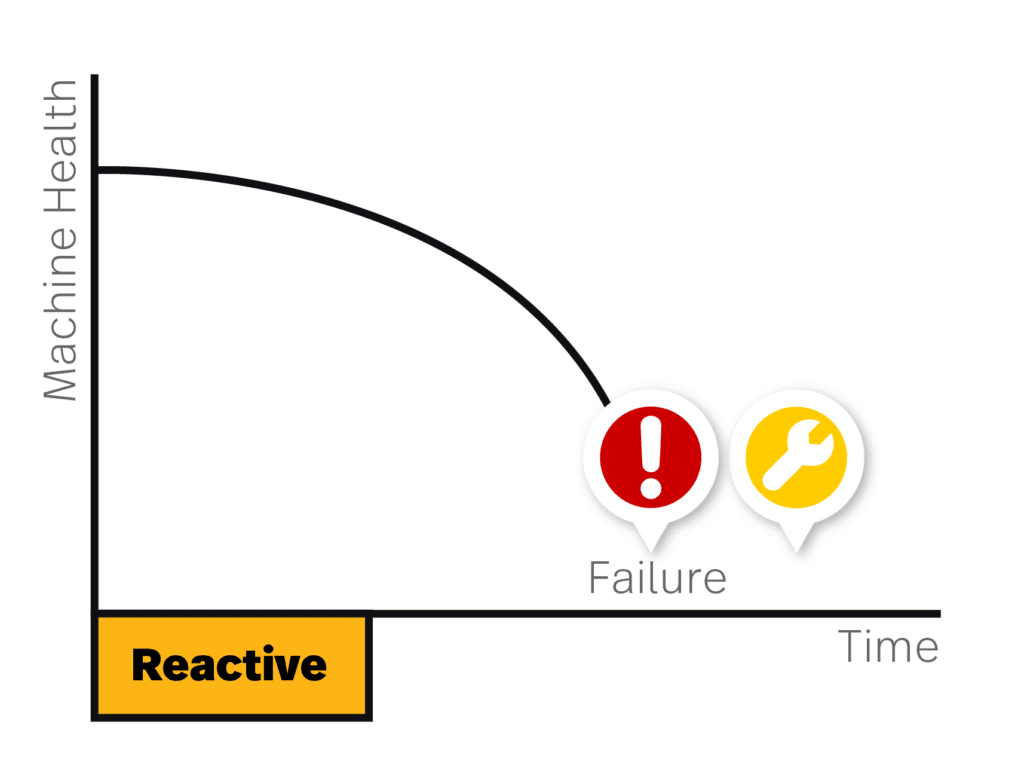

Reactive Maintenance

>55% of systems

The reactive, break-fix approach only replaces components when they fail.

Although this method is the most popular, it is far from efficient, leading to crippling and expensive consequences. The unexpected downtime caused by equipment failure can cost companies millions in lost revenue.

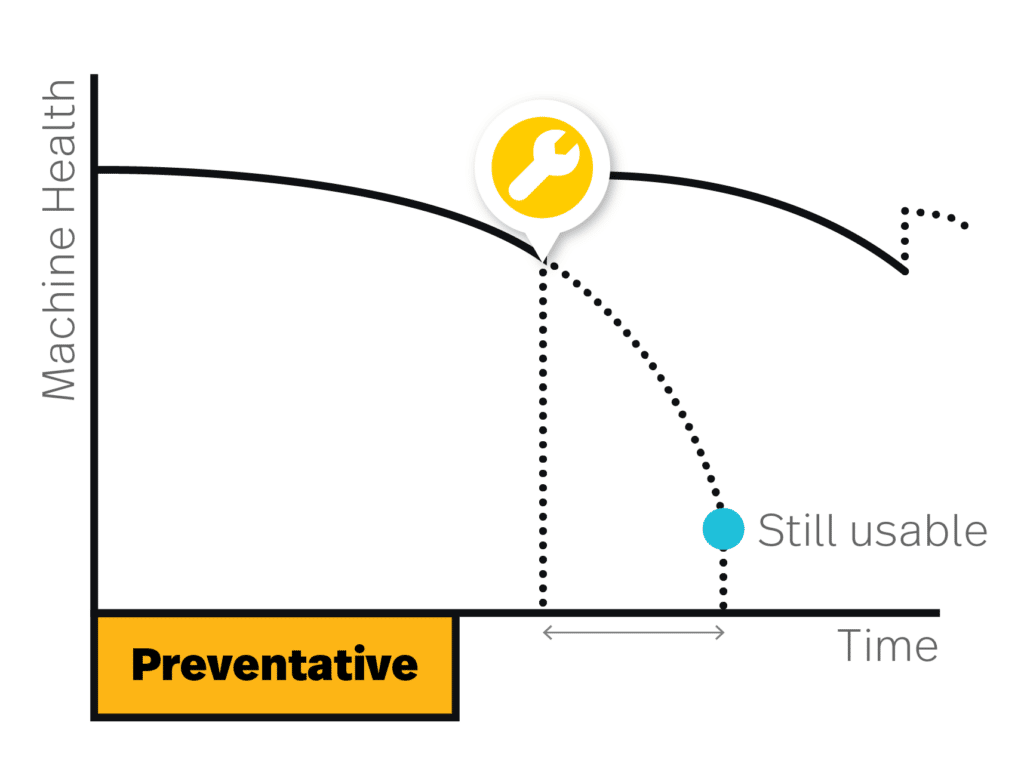

Preventative Maintenance

31% of systems

Regular preventative maintenance addresses issues on a consistent schedule. This is a more cost-effective and time-efficient approach than reactive maintenance.

However, there are opportunities to reduce costs even further. With a preventative approach, all equipment is scheduled for downtime, even if it doesn’t require maintenance. This method wastes valuable resources as servicing a machine before necessary wastes machine life, misallocates maintenance resources, and increases the cost of doing business.

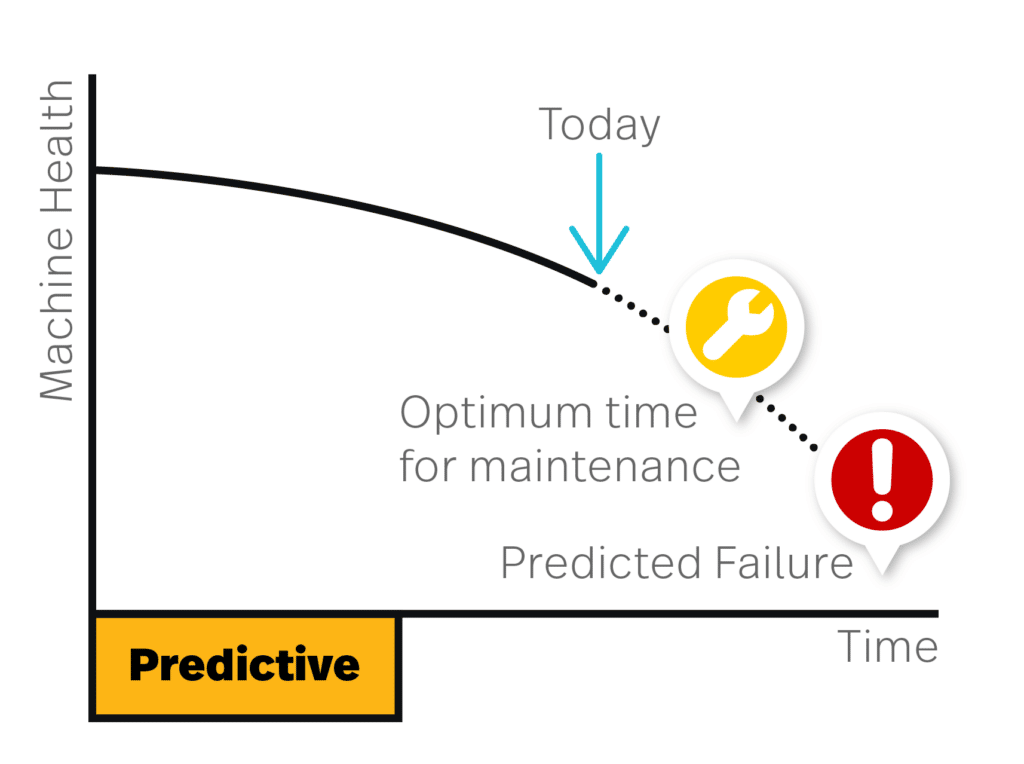

Predictive Maintenance

12% of systems

Predictive maintenance allows companies to forecast when different parts of a machine will fail. This method is the most efficient, maximizing the useful life of industrial parts while preventing unexpected downtime.

While this is the most cost-effective approach for plant maintenance, it is also the most difficult to implement. Forecasting through traditional methods does not provide the precision required for predictive machine maintenance.

Improved predictive models can provide near-perfect accuracy by leveraging reliable data and ML algorithms. With the ability to predict impending machine failure, maintenance teams can anticipate downtime to extract the remaining life from the machine.

The ROI of Predictive Maintenance

When equipment fails unexpectedly, companies must undergo a process of discovery, containment, and recovery. Troubleshooting and remediation incur significant operating costs over and above the associated capital equipment costs. Reduced employee productivity and supply chain disruptions during this period result in additional expenses for the company.

Given this extensive list of expenses, it’s unsurprising to find that the average cost of downtime is more than $260,000 per hour.

Switching to a predictive maintenance approach can deliver a significant return on investment.

Research from Deloitte suggests that predictive maintenance enhances equipment availability by 10 to 20%, simultaneously slashing total maintenance expenses by 5 to 10% and streamlining maintenance scheduling by 20 to 50%.

Independent surveys show that switching to a predictive maintenance program results in a 10x return on investment on average for industrial applications.

Addressing Problems With Predictive Maintenance

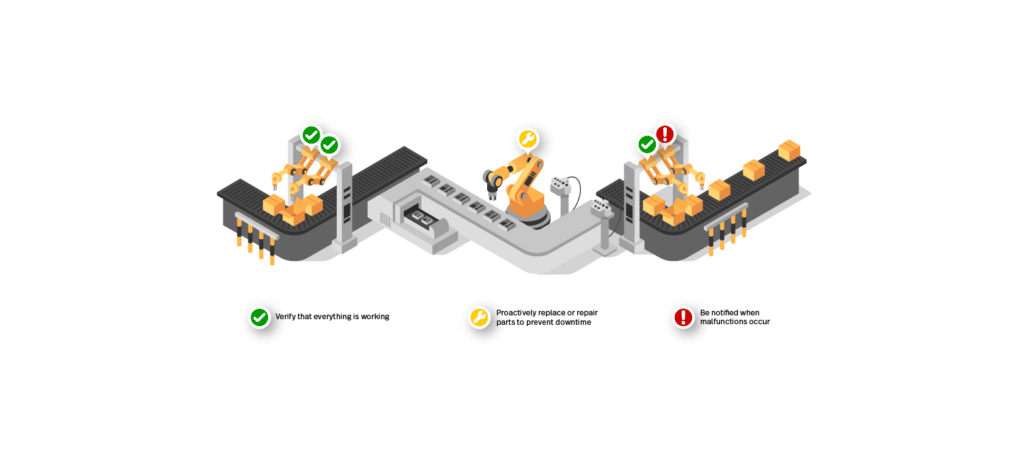

Very is an IoT technology firm led by a team of expert problem-solvers. We leverage data from IIoT devices to address a wide range of maintenance issues. While each client has different goals, we’ve identified some common key problems for industrial applications:

Common Issues Very Addresses

- Determining the Point of Failure. We’ll predict when a component will fail to minimize troubleshooting time and speed up repairs.

- Detecting Incipient Failure. We can use recorded sensor data to detect failures, before they result in downtime, by training an ML model to detect anomalies.

- Maximizing Remaining Useful Life. With the ability to predict the interval before a component fails, we can apply maintenance or replace components at precisely the correct times.

The more accurately we can predict when a part of a machine will fail, the easier it is to achieve maximum productivity and efficiency in the plant. We use machine learning to build a predictive maintenance model to create a highly efficient, productive plant.

Typical Improvements

Optimized Workforce:

- Eliminate non-essential maintenance tasks

- Monitor machine function with fewer resources

- Increase labor usage rates

Improved Machine Productivity:

- Predict productivity levels

- Maximize machine and part life

- Maintain peak equipment effectiveness

Reduced Risk:

- Improve workplace safety

- Identify previously unknown variables

- Create predictable capacity

Succeeding With Predictive Maintenance

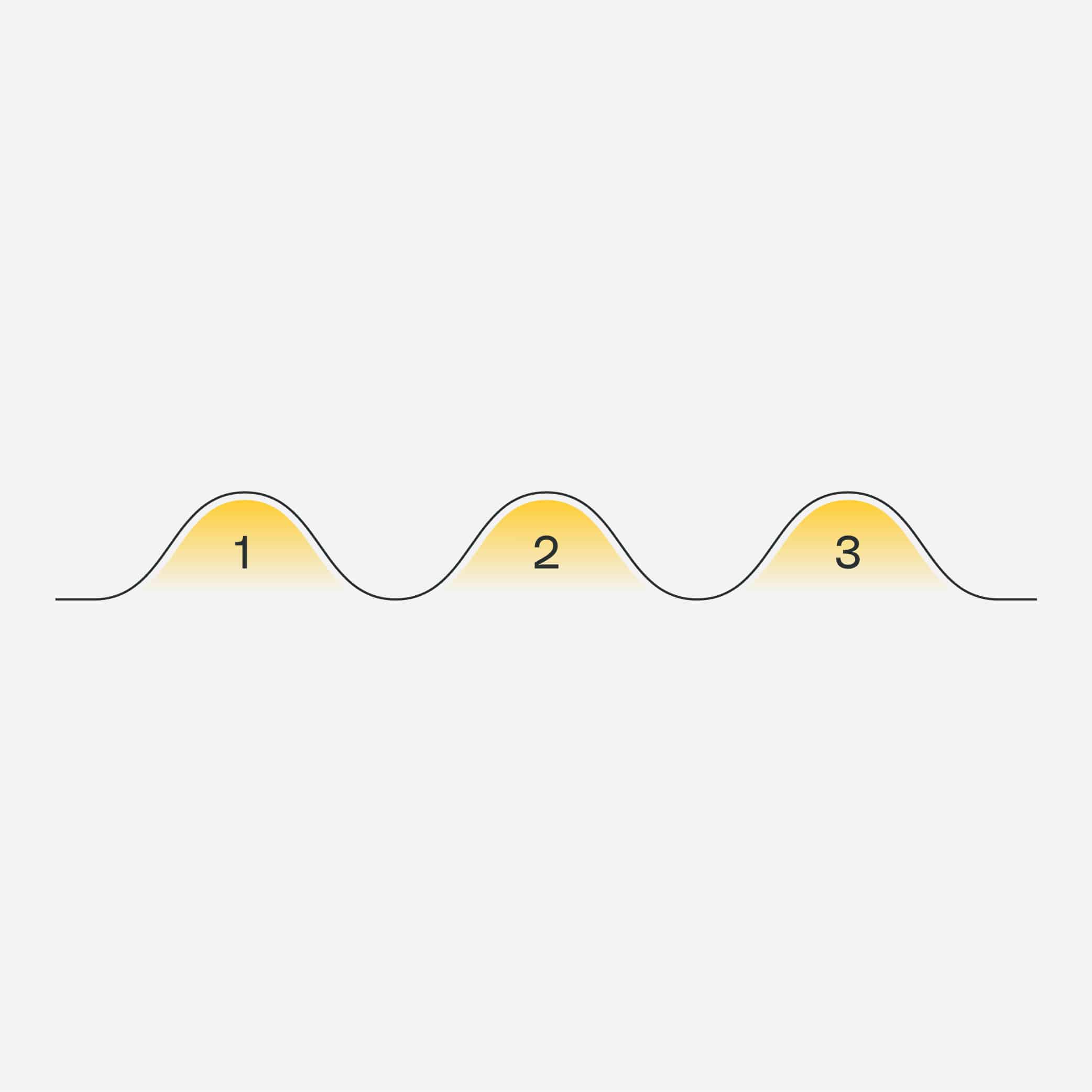

Predictive maintenance succeeds when the following three aspects are present: quality data, focused data filtering, and a well-defined context.

Obtain High-Quality Data

First, you need quality data. Ideally, you want historical data that reflects past event failures. This data is compared against static features of the machine, including average use, general properties, and operating conditions. Machine manufacturers can utilize aggregate data from thousands of machines to inform predictions.

Find the Right Focus

With an abundance of data, it is critical to focus on the right data. Don’t get distracted by extraneous information that deflects attention away from what is most important. Some questions to ask yourself to stay on track include:

- What failures are likely to occur?

- Which ones should be predicted?

- When a process fails, does it fail fast, or does it break down slowly over time?

Establish Context

Finally, take a close look at any other related systems and parts. Are there other components that are related to the failure? Can their performance be measured? How often do these measurements need to happen?

For best results, data collection needs to take place over an extended period. Shorter periods will narrow the field of possibilities and reduce the reliability of your insights. The time investment is worth it — quality data results in a more accurate predictive model.

Analyze the data and ask yourself or a trusted partner if it is possible to build a predictive model based on the available information. It is crucial to have the proper context when looking at a problem to evaluate predictions with accuracy.

Creating New Streams of Revenue

Using a predictive model minimizes the costs associated with plant maintenance while allowing you to predict the capacity of a plant with greater accuracy. Remember, manufacturers face 800 hours of equipment downtime annually, translating to over 15 hours each week.

Beyond saving money, companies can even generate revenue with predictive maintenance by selling the additional capacity to new contracts. You can also plan upcoming contracts based on scheduled maintenance windows to maintain your SLAs and optimize your downstream supply chain logistics.

Responding to the Needs of Connected Plants

Share data from the predictive failure models to inform maintenance plans for the plants’ suppliers. This data sharing could lead to the next level of just-in-time provisioning for key consumables, wear parts, or other important maintenance items.

By gathering detailed data from inside the plants of their customers, vendors can identify common failure modes, estimate the timing and volume of replacement parts needed, and share information with the plants to inform their predictive maintenance models.

Vendors can also use this information to develop new products and solutions to mitigate or eliminate the most common failure modes — even monetizing them through one-off sales or subscription offering bundles.

For example, a subscription that integrates monitoring using embedded IIoT devices with a just-in-time product or service delivery would provide a seamless experience for plant maintenance while ensuring a consistent source of business for the vendor.

Spreading the expense out in smaller increments across the product’s life also helps both the plant and vendor to navigate the procurement hurdles posed by large capital expenditures.

Reduce the time you spend on tedious support tickets, long SLAs, slow troubleshooting, and part supply logistics. Connecting and sharing predictive maintenance information aligns plants and vendors to overcome common inefficiencies and sources of frustration.